Wil Mathys

|

A Visit to MOS Technology

Recently my offer to get pictures of the MOS Technology building resulted in a drive to Rittenhouse Road in Norristown for the first time in at least 20 years. Unfortunately, my visit there can only be described as very, very depressing. Here are some notes:

As I turned onto Rittenhouse Road, I must say that I felt fairly optimistic about what I would see at 950 Rittenhouse Road. As I drove toward my destination, I encountered a number of new buildings where there had been empty fields and, at the same time, the buildings which had been there in the past looked to be occupied by active, successful companies. Unfortunately, when I arrived at the MOS Technology building, I encountered a completely different picture.

To understand the sad state of the building at 950 Rittenhouse Road, it’s important to go back to the time when the property was declared a “superfund site”. The EPA had uncovered the fact that chemicals used in the production of integrated circuits had leaked into the groundwater. During the years that followed, this superfund designation was a dark shadow over every attempt to sell the property or to put it to good use. For anyone interested in a little history, I would suggest googling ‘GMT Microelectronics’. You will uncover a large number of web sites dealing with attempts (and subsequent failures) to build a successful semiconductor manufacturing facility at this site. It is very interesting and at the same time very sad.

One of my clearest memories from the early days at MOS was the image of water being sprayed into the air from a well located next to the parking lot entrance. My understanding was that this would allow the contaminants to evaporate and would eventually eliminate the groundwater pollution. Arriving at my destination, the first thing I noticed was concrete blocks across the entrance to the parking lot but immediately after that I noticed that the water spray was gone. Hopefully the contamination problem has been resolved.

As I drove past the front of the building at 950 Rittenhouse Road, the first thing I noticed was that the building seemed to be empty, there were no lights on in any of the windows and the grass had not been mowed for some time. Another thing I noticed is that the front of the building was covered with the remnants of poison ivy. Someone had taken down the poison ivy but had not cleaned up the patches of vegetation which poison ivy tends to leave behind.

The circular drive which runs past the front door was not in great shape but it provided a place to park so I pulled in. As I did I was reminded of the days when the front drive was reserved for visitors and upper management. In fact, the only image that remains is seeing John Paivenin’s split-window Corvette coupe sitting in the front drive.

While pulling into the drive, I noticed that there were a number of Asplundh trucks parked at the end of the building. No cars, just the trucks. If nothing else, this held out hope that some part of the building was being used.

After taking some photos of the front of the building, I decided to walk around the entire facility to see if there were any signs of life. In the process I discovered a couple of small buildings and a large back parking lot, all of which were new. To my surprise there were quite a number of cars in the lot. However, the lack of activity suggests that these belonged to Asplundh personnel who were working at other locations.

The other major surprise was a large addition to the building. It had four floors (the original building had just two). There was no sign of life in this addition. I assume that this was built by one of the companies that had managed to acquire the building after resolving the issues surrounding the superfund designation.

The only other surprise was a beautiful sign located in front of this addition. Molded into the sign were the words ‘GMT Microelectronics’. I had heard that a new company had attempted to manufacture integrated circuits there so I assume this was the company. In fact most of the web sites uncovered by subsequent googling efforts discussed two subjects: GMT Microelectronics and the superfund cleanup efforts.

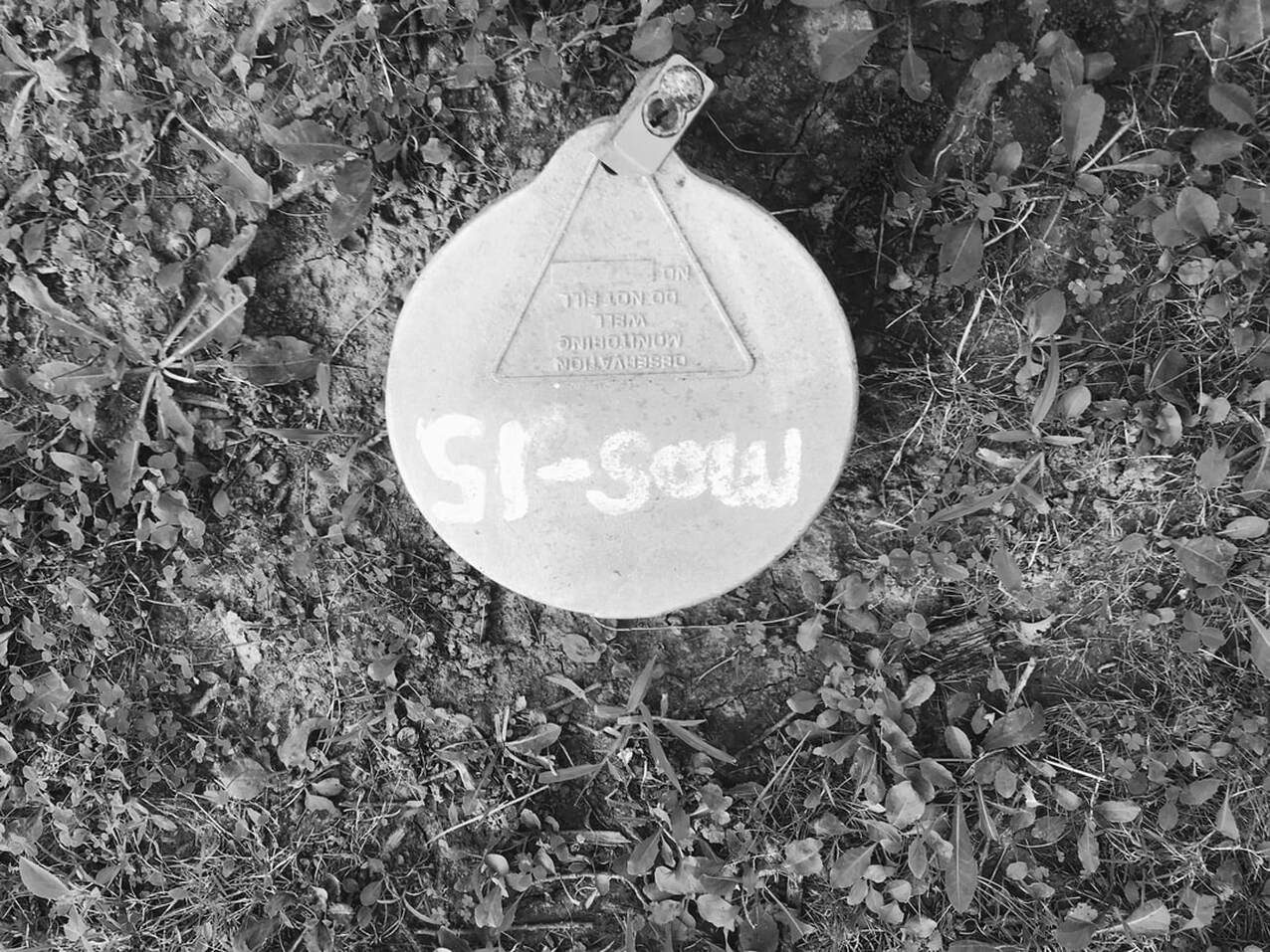

I walked around the entire building but found no signs of life other than the cars in the parking lot. I was struck by the lack of any evidence that MOS Technology ever existed there. However I finally ran into a 4” pipe in the front lawn on which was painted “MOS 15”. I can’t be sure but I would like to think that this is the reference I was searching for.

As I walked past the front entrance, I noticed that one of the doors was wide open so I went in just far enough to see if anything would look familiar. Unfortunately, all I saw was devastation. The building was gutted and the floor was wet enough to lead one to believe that there had been a significant roof leak. In the gloom one could hear a number of fans trying to dry things out (presumably). At that point my depression was complete. I climbed into my car and went home.

As I turned onto Rittenhouse Road, I must say that I felt fairly optimistic about what I would see at 950 Rittenhouse Road. As I drove toward my destination, I encountered a number of new buildings where there had been empty fields and, at the same time, the buildings which had been there in the past looked to be occupied by active, successful companies. Unfortunately, when I arrived at the MOS Technology building, I encountered a completely different picture.

To understand the sad state of the building at 950 Rittenhouse Road, it’s important to go back to the time when the property was declared a “superfund site”. The EPA had uncovered the fact that chemicals used in the production of integrated circuits had leaked into the groundwater. During the years that followed, this superfund designation was a dark shadow over every attempt to sell the property or to put it to good use. For anyone interested in a little history, I would suggest googling ‘GMT Microelectronics’. You will uncover a large number of web sites dealing with attempts (and subsequent failures) to build a successful semiconductor manufacturing facility at this site. It is very interesting and at the same time very sad.

One of my clearest memories from the early days at MOS was the image of water being sprayed into the air from a well located next to the parking lot entrance. My understanding was that this would allow the contaminants to evaporate and would eventually eliminate the groundwater pollution. Arriving at my destination, the first thing I noticed was concrete blocks across the entrance to the parking lot but immediately after that I noticed that the water spray was gone. Hopefully the contamination problem has been resolved.

As I drove past the front of the building at 950 Rittenhouse Road, the first thing I noticed was that the building seemed to be empty, there were no lights on in any of the windows and the grass had not been mowed for some time. Another thing I noticed is that the front of the building was covered with the remnants of poison ivy. Someone had taken down the poison ivy but had not cleaned up the patches of vegetation which poison ivy tends to leave behind.

The circular drive which runs past the front door was not in great shape but it provided a place to park so I pulled in. As I did I was reminded of the days when the front drive was reserved for visitors and upper management. In fact, the only image that remains is seeing John Paivenin’s split-window Corvette coupe sitting in the front drive.

While pulling into the drive, I noticed that there were a number of Asplundh trucks parked at the end of the building. No cars, just the trucks. If nothing else, this held out hope that some part of the building was being used.

After taking some photos of the front of the building, I decided to walk around the entire facility to see if there were any signs of life. In the process I discovered a couple of small buildings and a large back parking lot, all of which were new. To my surprise there were quite a number of cars in the lot. However, the lack of activity suggests that these belonged to Asplundh personnel who were working at other locations.

The other major surprise was a large addition to the building. It had four floors (the original building had just two). There was no sign of life in this addition. I assume that this was built by one of the companies that had managed to acquire the building after resolving the issues surrounding the superfund designation.

The only other surprise was a beautiful sign located in front of this addition. Molded into the sign were the words ‘GMT Microelectronics’. I had heard that a new company had attempted to manufacture integrated circuits there so I assume this was the company. In fact most of the web sites uncovered by subsequent googling efforts discussed two subjects: GMT Microelectronics and the superfund cleanup efforts.

I walked around the entire building but found no signs of life other than the cars in the parking lot. I was struck by the lack of any evidence that MOS Technology ever existed there. However I finally ran into a 4” pipe in the front lawn on which was painted “MOS 15”. I can’t be sure but I would like to think that this is the reference I was searching for.

As I walked past the front entrance, I noticed that one of the doors was wide open so I went in just far enough to see if anything would look familiar. Unfortunately, all I saw was devastation. The building was gutted and the floor was wet enough to lead one to believe that there had been a significant roof leak. In the gloom one could hear a number of fans trying to dry things out (presumably). At that point my depression was complete. I climbed into my car and went home.

This is the only evidence that MOS Technology ever existed at the Norristown, PA campus

Evidence that someone tried to build integrated circuits after MOS Technology went down.

The back of the MOS Technology building.

A Little History Lesson

Published June 6, 2022

In the late 60's/early 70's, I lived in Cincinnati and was involved in the design of early cash machines, called automated tellers at the time. At the time, minicomputers were just a little too expensive to be put in an automated teller so small scale integrated circuits had been used to implement a processor capable of controlling the system. Since my background and education were in digital design and since I have never interviewed for a job without getting it, I was hired to implement the interface between the processor and the peripheral devices (bill dispenser, keyboard, etc).

This project was well under way for me when a high-level decision was made to cancel the in-house processor and to redesign the system around the PDP-11 minicomputer. This new computer architecture was not cheap but was very effective. My part in the project did not change but my subsequent experience with computer architecture certainly did.

About this time, the Intel 8080 microprocessor had been released and (I didn't know it at the time) Motorola was attempting to join the microprocessor fray. Motorola's microprocessor, the 6800, was being designed by a team consisting of personnel from Computer System Marketing and the chip design group. The marketing group had joined the effort because of a lack of computer architecture experience in the chip design group. I didn't realize it at the time but the atmosphere at Motorola had become quite political. I was hired to design the 6800 peripheral devices because marketing was attempting to exercise increased power over the 6800 project.

One summer day in 1973 I was talking to a Motorola sales representative who mentioned that Motorola was looking for people for the 6800 project. He asked if I would be interested and I replied in the affirmative. A few days later I got a phone call from someone at Motorola and a visit to Phoenix was arranged. The result, as they say, was history. I didn't realize what I was getting into at the time, but as I said before, I have never interviewed for a job without getting it. I was hired to work on the 6800 interface chips.

I realized shortly after the move to Phoenix that I was working in the Computer Systems Marketing department but that didn't matter. I was working on the 6800 interface design. Even more importantly, I was working on integrated circuits. I had much to learn but here was an excellent learning opportunity.

Please note that the chip design department and the marketing department were in different buildings. In fact, they were in different towns. My plan to become familiar with integrated circuit design was pretty much stillborn, especially when my boss suggested that marketing people had no reason to go over to Mesa, the home of chip design. My solution was to transfer to the chip design department in hopes of finally escaping what had become quite a very strange political environment.On one of my last visits to Mesa before I actually transferred there, I was introduced to a guy named Chuck who had been hired into the chip design department as their chip architect, primarily for the 6800 microprocessor. I will admit that I did not think too much about it at the time except that it seemed to be just another move in the politics of engineering. Chip design was attempting to take back control of system design.

That evening I went with my family to visit the Scottsdale airport to see if they had planes to rent since I had recently obtained my pilot's license. With the glorious weather in Phoenix, I was sure flying would be equally glorious. During the visit, I ran into the same Chuck that I had met that day at Motorola. He was meeting with some potential investors that would allow him to restart his company. His company had developed a "Point of Sale" terminal and had simply run out of money. Chuck had agreed to join Motorola out of desperation but let there be no doubt where his loyalties lay.

I don't remember what happened with the investors but I do remember determining that he had bought a house within less than block of mine in Scottsdale and that his last name was Peddle. This was the start of an interesting if not beautiful friendship.

During the ensuing months Chuck and I became friends, often meeting at his house for lengthy conversation. This often touched on the current status of the microprocessor world and more importantly on the question of just how we could get a piece of it for ourselves. The reality is that I was at Motorola to widen my microprocessor and semiconductor experience. Chuck was there because his previous attempt at a point of sale terminal had run out of money and he was looking for his next opportunity. After many conversations it became apparent that Chuck was talking to a number of other Motorola personnel. This included marketing as well as engineering. In fact, he had put together a full engineering, marketing and management team and was searching for a sponsor. I will admit that it was a bit heady to think that I was included in the engineering part of this team. Eventually it became obvious that he was not expecting to be involved in the day-to-day design and he hoped that I could interpret his thoughts and could help turn them into an architecture and ultimately into a chip. As described below, it took a great deal of effort but I proved quite capable of doing so. Skipping over a long period of time in which Chuck was visiting different companies looking for one that was interested in developing a microprocessor, there came a day when he told me he had heard about a small company in Pennsylvania called MOS Technology. They had been producing calculator chips and might be interested. After several visits to the Philadelphia area, it was all worked out. Each of seven people would be given $10,000 to allow them to relocate to Audubon, PA. When it all came down, a arrangement was made with a local apartment complex to rent five units for six months. Buying a house was put off until after the design was complete. One week after resigning from Motorola we were all at MOS Technology.

Before I proceed to describe our design activity, it might be useful to describe the steps which go into producing a microprocessor design. As you will see, the skills required for each step are quite different. That means that there were phases of the project which I shared with other people, phases which were solely my responsibility and phases which to me were solely black magic and which relied on some very smart and very highly educated engineers.

The steps required to design a microprocessor can be listed as follows:

1. Definition of the architecture. This includes the registers, the instructions and things like interrupts, etc. It may also include some things like temporary registers which are required to execute the instruction set and the busses which will be needed for transferring data into and out of the registers. I participated fully in this phase, mostly taking responsibility for the documentation, making sure that it all made sense and making sure that we would have an effective computer when all was said and done.

2. Detailed definition of the instruction set execution. This is done mostly by defining the data transfers which take place in and out the registers or in and out of the chip.

This phase was entirely my responsibility. I took input from other people but it was my job to have something which documented exactly what took place with each instruction. It had to be in very detailed form because it specified exactly how our chip would perform.

3. Production of instruction execution information in logic form. This is done most effectively in the form of logic equations.

Note that there is nothing new in these logic equations. They merely present the instruction execution information in a form which can lead to logic diagrams. This was solely my responsibility.

4. Production of a logic diagram. The final step in generating something that can be used by the semiconductor gurus to produce a chip is the production of a complete logic diagram. Every transistor, every bus, every support circuit, etc. must be included. Basically the rule is that if it is not on the logic diagram, it will not be on the chip. The logic diagram was solely my responsibility.

5. When the logic diagram is complete, the circuit designers and layout draftsmen take over. My job is complete. Believe me, the circuit designers are technically very skilled and very highly educated. I can produce a very meaningful set of logic diagrams but without the circuit designers and layout draftsmen there would be no microprocessor.

The design process at MOS Technology commenced immediately after we arrived with my attempts to define the registers and instruction set which were to be our chip. This was relatively straightforward since it was to be an 8-bit processor with a standard program counter, and (I assumed) a sixteen-bit index register. I should point out that while my background left me with lots of experience with processor architecture, Chuck's experience left him with extensive experience with that set of applications at which the microprocessor was directed.

Behind all this was the fact that the cost of any chip is a function of the chip size. Anything we could do to reduce the chip size would be beneficial. One morning as I was struggling with the 16-bit index register and how to reduce the size of the increment/decrement logic, Chuck came in and proceeded to describe his thoughts. Based on his experience with the POS system design, he figured that we could have two 8-bit index registers instead of one 16-bit register along with two accumulators.

It seems like a wash at first but in reality this represented a truly significant reduction in circuitry. We couldn't avoid the need to increment and decrement the index register but certainly an 8-bit incrementer was significantly smaller than a 16-bit one. Chuck's experience was that eight bits would do the job and I certainly had no experience suggesting that he was wrong. By late morning our microprocessor design was pretty much defined. I am more than willing to give Chuck credit for the basic chip architecture, taking credit only for being able to understand its significance and being able to turn it into a logic diagram.

In the process of discussing the design, we worked out just what documentation would be generated. It started with about five 17" X 22" pages of state diagrams. These state diagrams defined the registers, the instruction set and just how the instructions were to be executed. Even more importantly, it documented the one-level pipelining which we planned to implement in our processor.

In reality, it cannot be emphasized too strongly that this state diagram was the design. Everything that followed was just another way of presenting the same information. Any inaccuracy in this documentation would be reflected in the chip. I spent many hours analyzing these diagrams assuring that they were both complete and completely accurate. Converting the state diagrams into a form that could be used to create a chip, i.e. a logic diagram, was my responsibility.

The first step toward the creation of the logic diagrams as needed by the circuit designers and the chip layout personnel was the creation of logic equations. These put the data transfers defined in the state diagrams into a form which can be used to implement the control logic in the chip.

When the equations were complete, the final step in my contribution commenced. This was the creation of a complete logic diagram which first documents the register section along with the busses which would be needed to carry out the instruction set. Along The top edge of the register section contains the control lines which cause data transfers into and out of the registers and onto and off of the busses. Additional pages would be required to document the logic which drives these lines based on the contents of the state register and the instruction register.

After the logic diagram was complete, my job was done except for answering questions. I found myself looking for things to do. For starters, someone mentioned that this would be a new architecture and would require manuals. I was familiar enough with the 6502 to write the owner's manual which was produced by a local printer. At the same time, I helped define a number of peripheral devices which completed the family of chips.

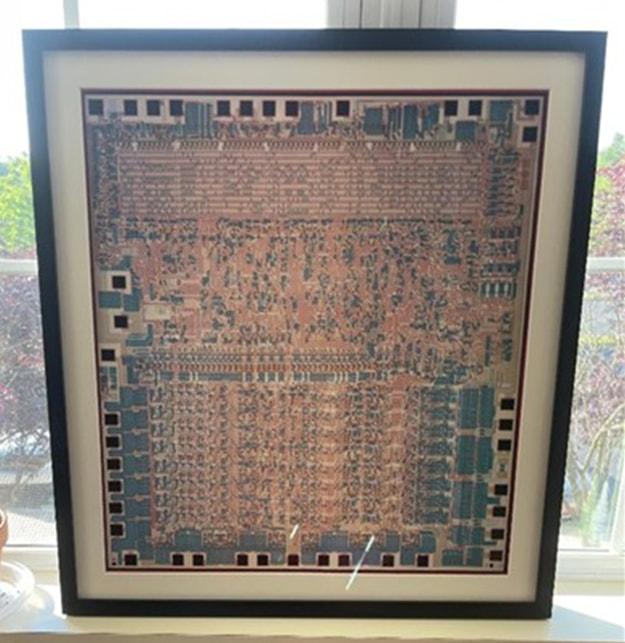

In the meantime, the circuit designers and the layout draftsmen took the logic diagram, carried out the necessary circuit analysis and manually converted the logic diagrams into the layout shown in the photograph. Finally, the 6502 was complete and it was time to show it to the world. That became my new challenge. For the ensuing months, I responded to requests from sales representatives by lecturing to potential customers and showing them how one achieves equal performance in a microprocessor half the size.

One of my most delightful requests came from a professor of computer science at the University of Chicago. He was teaching a graduate class in computer architecture and wanted me to lecture to the class on the tradeoffs which can be made in the design of microprocessors. I did so for each new class. In other words, once a semester I went to the University of Chicago and lectured to their graduate computer science students.

This project was well under way for me when a high-level decision was made to cancel the in-house processor and to redesign the system around the PDP-11 minicomputer. This new computer architecture was not cheap but was very effective. My part in the project did not change but my subsequent experience with computer architecture certainly did.

About this time, the Intel 8080 microprocessor had been released and (I didn't know it at the time) Motorola was attempting to join the microprocessor fray. Motorola's microprocessor, the 6800, was being designed by a team consisting of personnel from Computer System Marketing and the chip design group. The marketing group had joined the effort because of a lack of computer architecture experience in the chip design group. I didn't realize it at the time but the atmosphere at Motorola had become quite political. I was hired to design the 6800 peripheral devices because marketing was attempting to exercise increased power over the 6800 project.

One summer day in 1973 I was talking to a Motorola sales representative who mentioned that Motorola was looking for people for the 6800 project. He asked if I would be interested and I replied in the affirmative. A few days later I got a phone call from someone at Motorola and a visit to Phoenix was arranged. The result, as they say, was history. I didn't realize what I was getting into at the time, but as I said before, I have never interviewed for a job without getting it. I was hired to work on the 6800 interface chips.

I realized shortly after the move to Phoenix that I was working in the Computer Systems Marketing department but that didn't matter. I was working on the 6800 interface design. Even more importantly, I was working on integrated circuits. I had much to learn but here was an excellent learning opportunity.

Please note that the chip design department and the marketing department were in different buildings. In fact, they were in different towns. My plan to become familiar with integrated circuit design was pretty much stillborn, especially when my boss suggested that marketing people had no reason to go over to Mesa, the home of chip design. My solution was to transfer to the chip design department in hopes of finally escaping what had become quite a very strange political environment.On one of my last visits to Mesa before I actually transferred there, I was introduced to a guy named Chuck who had been hired into the chip design department as their chip architect, primarily for the 6800 microprocessor. I will admit that I did not think too much about it at the time except that it seemed to be just another move in the politics of engineering. Chip design was attempting to take back control of system design.

That evening I went with my family to visit the Scottsdale airport to see if they had planes to rent since I had recently obtained my pilot's license. With the glorious weather in Phoenix, I was sure flying would be equally glorious. During the visit, I ran into the same Chuck that I had met that day at Motorola. He was meeting with some potential investors that would allow him to restart his company. His company had developed a "Point of Sale" terminal and had simply run out of money. Chuck had agreed to join Motorola out of desperation but let there be no doubt where his loyalties lay.

I don't remember what happened with the investors but I do remember determining that he had bought a house within less than block of mine in Scottsdale and that his last name was Peddle. This was the start of an interesting if not beautiful friendship.

During the ensuing months Chuck and I became friends, often meeting at his house for lengthy conversation. This often touched on the current status of the microprocessor world and more importantly on the question of just how we could get a piece of it for ourselves. The reality is that I was at Motorola to widen my microprocessor and semiconductor experience. Chuck was there because his previous attempt at a point of sale terminal had run out of money and he was looking for his next opportunity. After many conversations it became apparent that Chuck was talking to a number of other Motorola personnel. This included marketing as well as engineering. In fact, he had put together a full engineering, marketing and management team and was searching for a sponsor. I will admit that it was a bit heady to think that I was included in the engineering part of this team. Eventually it became obvious that he was not expecting to be involved in the day-to-day design and he hoped that I could interpret his thoughts and could help turn them into an architecture and ultimately into a chip. As described below, it took a great deal of effort but I proved quite capable of doing so. Skipping over a long period of time in which Chuck was visiting different companies looking for one that was interested in developing a microprocessor, there came a day when he told me he had heard about a small company in Pennsylvania called MOS Technology. They had been producing calculator chips and might be interested. After several visits to the Philadelphia area, it was all worked out. Each of seven people would be given $10,000 to allow them to relocate to Audubon, PA. When it all came down, a arrangement was made with a local apartment complex to rent five units for six months. Buying a house was put off until after the design was complete. One week after resigning from Motorola we were all at MOS Technology.

Before I proceed to describe our design activity, it might be useful to describe the steps which go into producing a microprocessor design. As you will see, the skills required for each step are quite different. That means that there were phases of the project which I shared with other people, phases which were solely my responsibility and phases which to me were solely black magic and which relied on some very smart and very highly educated engineers.

The steps required to design a microprocessor can be listed as follows:

1. Definition of the architecture. This includes the registers, the instructions and things like interrupts, etc. It may also include some things like temporary registers which are required to execute the instruction set and the busses which will be needed for transferring data into and out of the registers. I participated fully in this phase, mostly taking responsibility for the documentation, making sure that it all made sense and making sure that we would have an effective computer when all was said and done.

2. Detailed definition of the instruction set execution. This is done mostly by defining the data transfers which take place in and out the registers or in and out of the chip.

This phase was entirely my responsibility. I took input from other people but it was my job to have something which documented exactly what took place with each instruction. It had to be in very detailed form because it specified exactly how our chip would perform.

3. Production of instruction execution information in logic form. This is done most effectively in the form of logic equations.

Note that there is nothing new in these logic equations. They merely present the instruction execution information in a form which can lead to logic diagrams. This was solely my responsibility.

4. Production of a logic diagram. The final step in generating something that can be used by the semiconductor gurus to produce a chip is the production of a complete logic diagram. Every transistor, every bus, every support circuit, etc. must be included. Basically the rule is that if it is not on the logic diagram, it will not be on the chip. The logic diagram was solely my responsibility.

5. When the logic diagram is complete, the circuit designers and layout draftsmen take over. My job is complete. Believe me, the circuit designers are technically very skilled and very highly educated. I can produce a very meaningful set of logic diagrams but without the circuit designers and layout draftsmen there would be no microprocessor.

The design process at MOS Technology commenced immediately after we arrived with my attempts to define the registers and instruction set which were to be our chip. This was relatively straightforward since it was to be an 8-bit processor with a standard program counter, and (I assumed) a sixteen-bit index register. I should point out that while my background left me with lots of experience with processor architecture, Chuck's experience left him with extensive experience with that set of applications at which the microprocessor was directed.

Behind all this was the fact that the cost of any chip is a function of the chip size. Anything we could do to reduce the chip size would be beneficial. One morning as I was struggling with the 16-bit index register and how to reduce the size of the increment/decrement logic, Chuck came in and proceeded to describe his thoughts. Based on his experience with the POS system design, he figured that we could have two 8-bit index registers instead of one 16-bit register along with two accumulators.

It seems like a wash at first but in reality this represented a truly significant reduction in circuitry. We couldn't avoid the need to increment and decrement the index register but certainly an 8-bit incrementer was significantly smaller than a 16-bit one. Chuck's experience was that eight bits would do the job and I certainly had no experience suggesting that he was wrong. By late morning our microprocessor design was pretty much defined. I am more than willing to give Chuck credit for the basic chip architecture, taking credit only for being able to understand its significance and being able to turn it into a logic diagram.

In the process of discussing the design, we worked out just what documentation would be generated. It started with about five 17" X 22" pages of state diagrams. These state diagrams defined the registers, the instruction set and just how the instructions were to be executed. Even more importantly, it documented the one-level pipelining which we planned to implement in our processor.

In reality, it cannot be emphasized too strongly that this state diagram was the design. Everything that followed was just another way of presenting the same information. Any inaccuracy in this documentation would be reflected in the chip. I spent many hours analyzing these diagrams assuring that they were both complete and completely accurate. Converting the state diagrams into a form that could be used to create a chip, i.e. a logic diagram, was my responsibility.

The first step toward the creation of the logic diagrams as needed by the circuit designers and the chip layout personnel was the creation of logic equations. These put the data transfers defined in the state diagrams into a form which can be used to implement the control logic in the chip.

When the equations were complete, the final step in my contribution commenced. This was the creation of a complete logic diagram which first documents the register section along with the busses which would be needed to carry out the instruction set. Along The top edge of the register section contains the control lines which cause data transfers into and out of the registers and onto and off of the busses. Additional pages would be required to document the logic which drives these lines based on the contents of the state register and the instruction register.

After the logic diagram was complete, my job was done except for answering questions. I found myself looking for things to do. For starters, someone mentioned that this would be a new architecture and would require manuals. I was familiar enough with the 6502 to write the owner's manual which was produced by a local printer. At the same time, I helped define a number of peripheral devices which completed the family of chips.

In the meantime, the circuit designers and the layout draftsmen took the logic diagram, carried out the necessary circuit analysis and manually converted the logic diagrams into the layout shown in the photograph. Finally, the 6502 was complete and it was time to show it to the world. That became my new challenge. For the ensuing months, I responded to requests from sales representatives by lecturing to potential customers and showing them how one achieves equal performance in a microprocessor half the size.

One of my most delightful requests came from a professor of computer science at the University of Chicago. He was teaching a graduate class in computer architecture and wanted me to lecture to the class on the tradeoffs which can be made in the design of microprocessors. I did so for each new class. In other words, once a semester I went to the University of Chicago and lectured to their graduate computer science students.

A Brief Look at the 6502 Chip Layout

Above is a photo of the artwork which I carried around the eastern half of the USA and which I used to show that we could achieve performance on a par with other microprocessors with approximately twice the chip size. Back in the mid-70s, the Intel 8080 was available for approximately $275. At the same time, the Motorola 6800 came out at roughly $175. When the 6502 was introduced, it sold for $25! This is not particularly impressive if one believes this to be a loss-leader price but it was not. It was a legitimate price based on the significant reduction in chip size.The chip artwork was particularly effective when I was lecturing to a bunch of engineers because it is very easy to identify the major sections. Certainly the concept of a register section and busses to transfer data between the registers was not new for most of the engineers and engineering students that I lectured to. Likewise, the notion of digital logic with its AND and OR terms was not new. The resulting $25 price is what allowed two college students as well as dozens of other personnel to create major, successful companies.

Here is a rundown on the chip layout. Each of the major sections is discussed separately below.

1. The register section

Easiest to identify is the register section which makes up roughly 40% of the chip. It sits directly across the bottom. Close examination easily reveals an eight-bit organization in the registers.

2. The control Logic AND Section

The AND gates are all independent. None feeds the other and all have the same set of inputs as seen along the top of the chip. As a result, this logic can be built in a very orderly, very organized array. I have always felt that anyone with a little digital logic experience could understand the huge amount of logic in this section with its 16 inputs (roughly) and about 126 outputs feeding down into the OR logic.

3. The control Logic OR section

This is where the skill of the layout draftsman comes front and center. No longer does he (or she) have a nice orderly structure as in the previous section. Suffice it to say that they manage to keep all the connections straight producing the logic exactly as shown on the logic diagram. This section occupies most of the area between the registers and the AND logic.

In addition, there are a number of elements which are a much smaller percentage of the chip but are critical to its operation, for example, the instruction register sits by itself directly above the right end of the register section. I believe the state counter sat to the left of the AND logic. It was my job to make sure all these elements were included in the logic diagram; it was the layout draftsman's job to find room for everything and because they are magicians, i.e. very skilled, they did exactly that.

Here is a rundown on the chip layout. Each of the major sections is discussed separately below.

1. The register section

Easiest to identify is the register section which makes up roughly 40% of the chip. It sits directly across the bottom. Close examination easily reveals an eight-bit organization in the registers.

2. The control Logic AND Section

The AND gates are all independent. None feeds the other and all have the same set of inputs as seen along the top of the chip. As a result, this logic can be built in a very orderly, very organized array. I have always felt that anyone with a little digital logic experience could understand the huge amount of logic in this section with its 16 inputs (roughly) and about 126 outputs feeding down into the OR logic.

3. The control Logic OR section

This is where the skill of the layout draftsman comes front and center. No longer does he (or she) have a nice orderly structure as in the previous section. Suffice it to say that they manage to keep all the connections straight producing the logic exactly as shown on the logic diagram. This section occupies most of the area between the registers and the AND logic.

In addition, there are a number of elements which are a much smaller percentage of the chip but are critical to its operation, for example, the instruction register sits by itself directly above the right end of the register section. I believe the state counter sat to the left of the AND logic. It was my job to make sure all these elements were included in the logic diagram; it was the layout draftsman's job to find room for everything and because they are magicians, i.e. very skilled, they did exactly that.